About Steelmate

Steelmate Co.,Ltd,founded in 1993,specializes in design,development,manufacture and sale of automotive electronics,such as parking assist syatem,car alarm system,motorcycle alarm system,tire pressure motitoring system,bhind spot detection system,baby seat alarm system etc.

In Steelmate industrial park,production lines are equipped with arrays of start-of-the-art automatic equipment,from Siemens and Yamaha SMT machinery,high-precision mold processing machine tools to advanced in-line and lab testing equipment.

With27-year technical experience accumulated,Steelmate has become a significant leader in aftermarket and a vigorous competitor in OE market in China,featuring in abundant in-house R&D capability,outstanding OEM service competence,standardized production capacity and reliable quality control ability.

Meanwhile,Steelmate is also actively expanding into internal market.By 2020,Steelmate products has been sold and well-received in more than 90 overseas countries and regions,bringing opportunities of cooperation with world-known enterprises,e.g.VALEO,TOYOTA.

With customer-oriented and innovative-centered principle,Steelmate has always been working to offer customers affordable quality products and services.

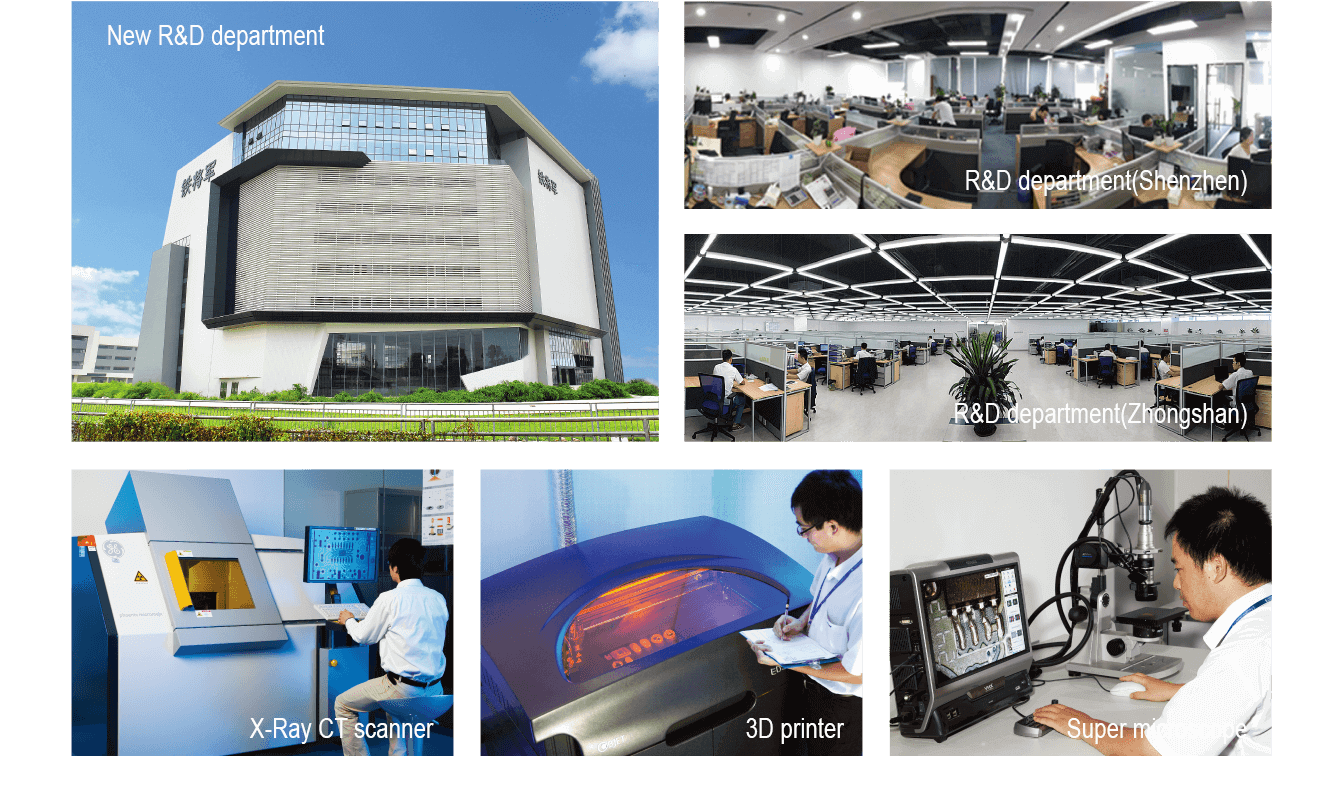

R&D Capacity

The key to Steelmate's success lies in the vision and commitment to our continuous efforts and enormous investment in R&D,Steelmate has streamlined its product mix and sharpened the technology.

With 120 elites in our R&D team in-house,Steelmate is able to launch new designs and products meeting the needs of our business partners all over the world.We carry out the entire product development procedures ourselves in respect of product design,PCB layout,testing and packaging designs.

In pursuit of the most advanced technology and craftsmanship,we have invested heavily on acquisition of best research equipment to achieve such goal.For instance,we have adopted a 3D printer and X-Ray CT scanner for prototype producing and componment checking respectively,considerably shortening the R&D cycle and delivery time.A well established RoHS lab will monitor our products to ensure RoHS compliance.These tactics enable us to deliver the quality product more quickly.

Steelmate develops the core technologies and designs on its own.At the moment we have taken approximately 400 patents on a global scale.

Manufacturing Capacity

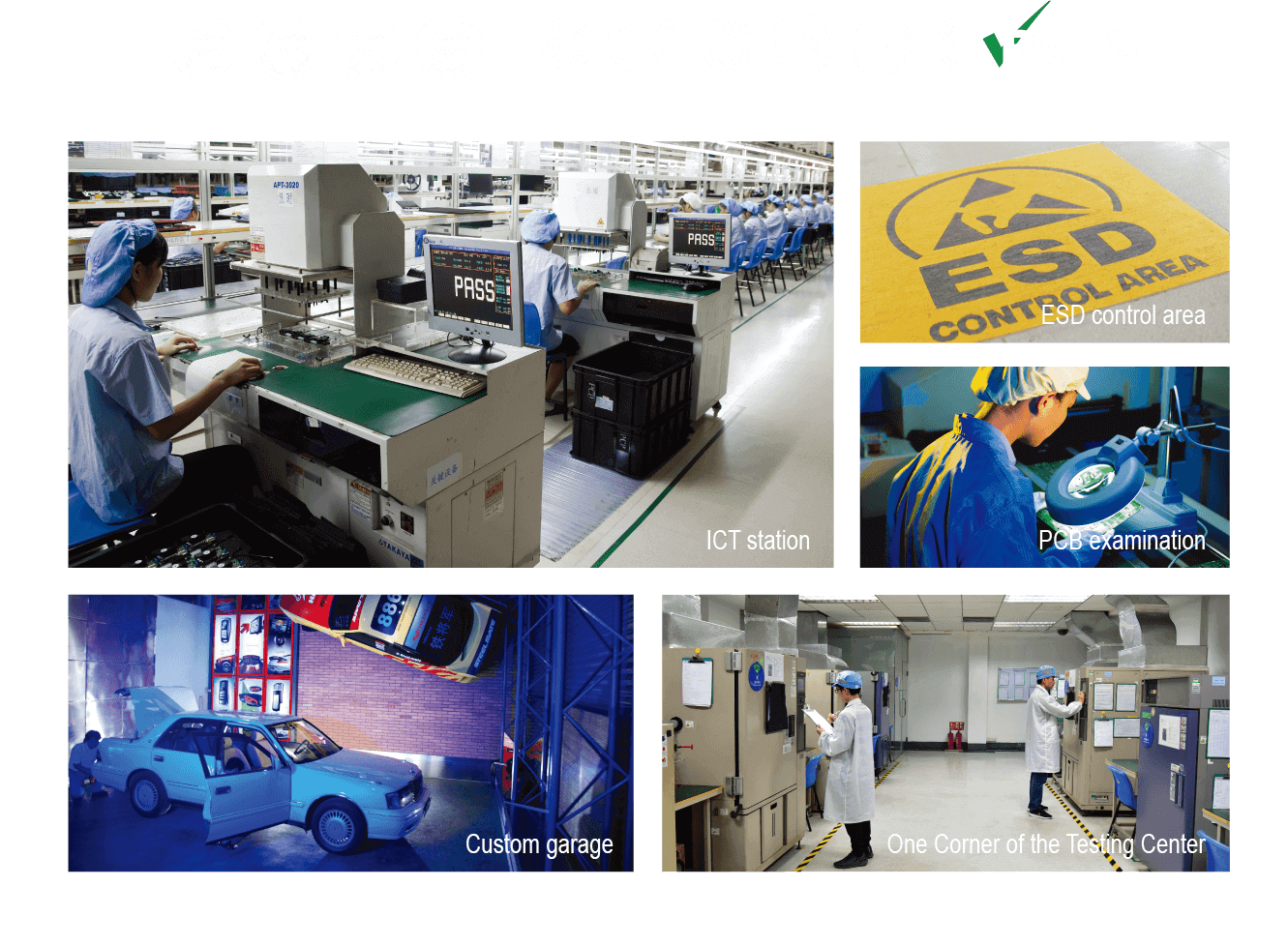

There are 10 automatic SMT lines(with 28 Siemens SMT machines) in the SMT center,10 lead-free double wave soldering lines and 10 ICT testing machines in the wave soldering workshop.

Apart from all these first class machines,there are 65 production lines which ensure a huge production caoacity.

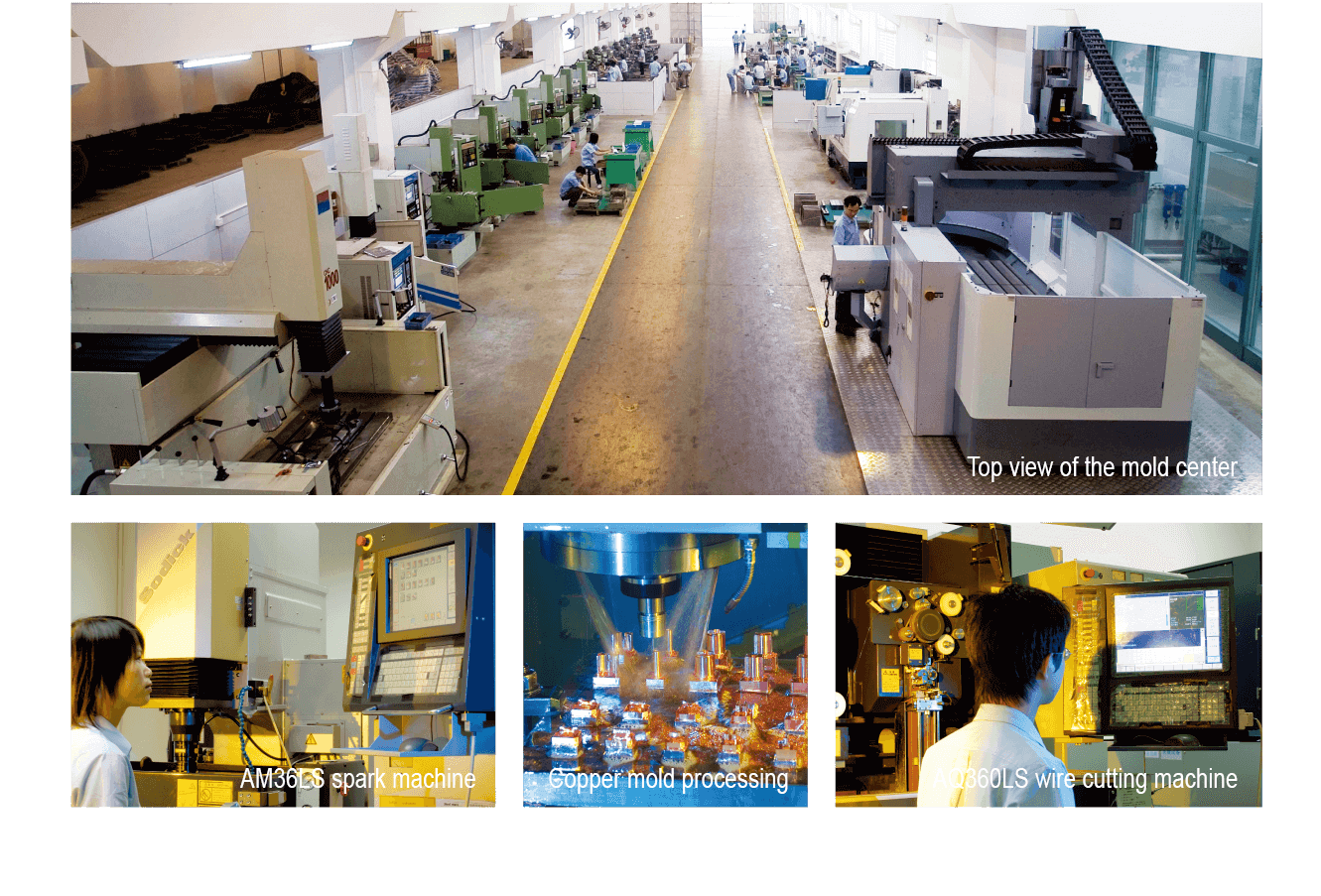

Mold Center

Our mold center is equipped with SODICK & SWISS high precision qeuipment sourced from Germany and Japan.All our molds are designed and made in-house.Currently,the mold center has the capacity to produce over 300 molds per year.

There are 70 staff in the mold center,including experienced structural engineers,technicians and senior technicians.With years of experience,we can provide custmization design to meet your specific market needs.

Quality Control

Quality Control is strictly carried out in the whole production procedure,form IQC to PQC. Unique designs,quality components,experienced employees,top class machines and ISO 9001,ISO/TS 16949 certified system are the guarantee of our quality products.Steelmate products ares CE,E-MARK,FCC and CCC certified.